How Does DTF Printing Work

Share

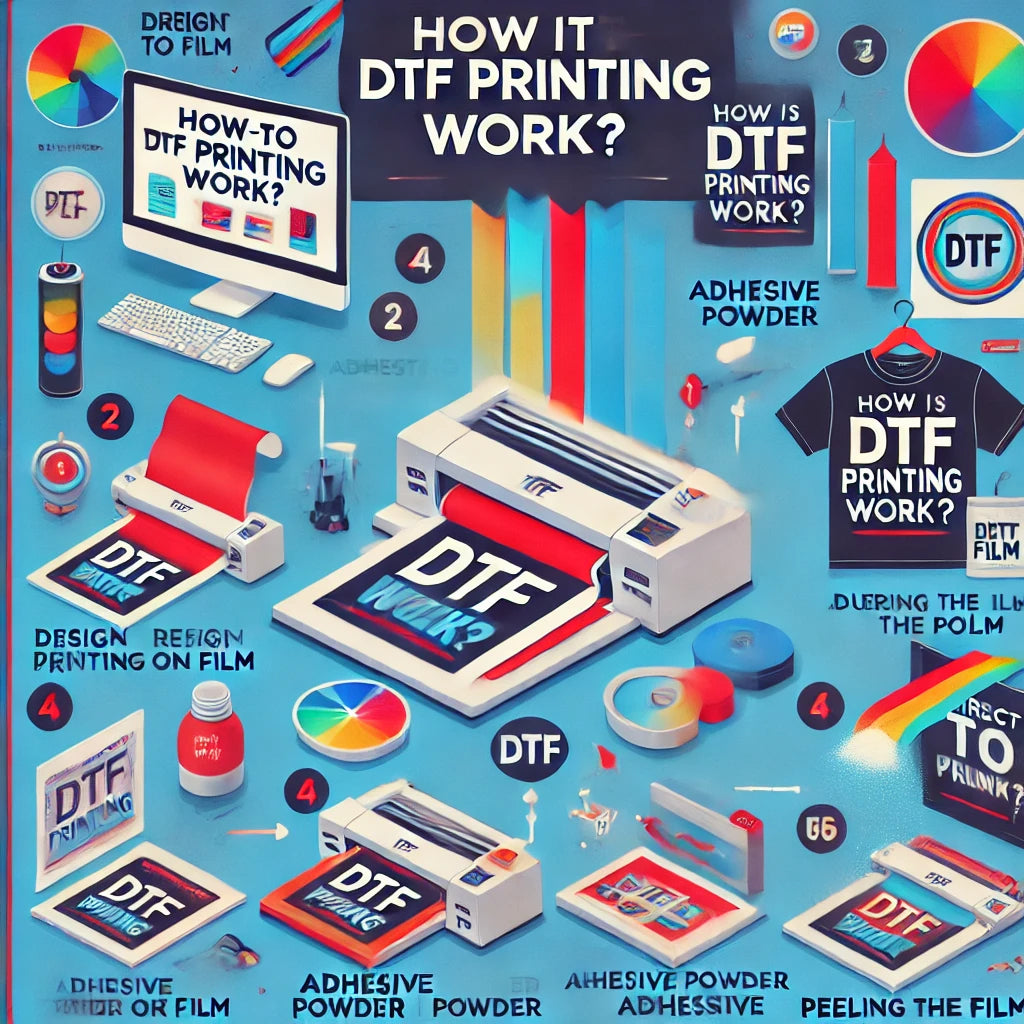

DTF (Direct-to-Film) printing is a step-by-step process that transforms digital designs into durable and vibrant transfers for garments and other surfaces. Here's how it works:

1. Design Creation

- The process begins with creating a digital design using graphic design software like Adobe Photoshop, Illustrator, or CorelDRAW.

- High-resolution files (300 DPI or more) ensure sharp and detailed prints.

- The design may include CMYK colors, gradients, and intricate details.

2. Printing on Transfer Film

- The design is printed onto a special PET (Polyethylene Terephthalate) film using a DTF printer.

-

Ink Used:

- A combination of CMYK (for colors) and white ink (to create a base layer for opacity and vibrant results).

-

Printer Type:

- Specialized printers equipped for DTF printing are used to ensure precision and even application.

3. Adhesive Powder Application

- A fine adhesive powder is sprinkled over the wet ink on the film.

- The powder adheres to the ink and serves as the "glue" that bonds the design to the fabric during heat pressing.

-

Key Points:

- Excess powder is shaken off to ensure a clean transfer.

- The adhesive powder must evenly coat the design.

4. Curing the Powder

- The adhesive powder is heated to melt and activate its bonding properties.

-

Curing Process:

- This can be done using a heat press or a curing oven at controlled temperatures.

- The powder solidifies to form a durable adhesive backing for the design.

5. Heat Transfer to the Fabric

- The cured film is placed onto the fabric with the design facing down.

- A heat press applies high pressure and heat (typically 160–180°C or 320–356°F) for 10–20 seconds.

- This heat activates the adhesive, transferring the design from the film to the fabric.

6. Peeling the Film

- After pressing, the film is peeled away from the fabric, leaving the design firmly attached.

-

Peel Type:

- Hot Peel: The film is removed while still warm.

- Cold Peel: The film is removed after it cools completely.

7. Final Press (Optional)

- A secondary heat press may be applied to ensure better adhesion and a smoother finish, improving durability and feel.

Key Features of DTF Printing

- Versatility: Suitable for almost all fabric types (cotton, polyester, blends, leather, etc.).

- Durability: Designs resist cracking, peeling, and fading.

- Vibrancy: Colors remain bright and sharp even after multiple washes.

- No Pre-Treatment Needed: Unlike DTG (Direct-to-Garment) printing, pre-treatment of the fabric isn't required.

DTF printing is a fast-growing technology due to its flexibility, affordability, and superior print quality, making it an ideal choice for custom apparel and merchandise businesses.